Instrument development

Development and construction of analytical equipment is a speciality of our institution and held in good tradition. Insight into the physics of mass spectrometers and their peripheral equipment together with well equipped mechanical and electronics workshops are pivotal to this success.

Currently on-going and completed developments of analytical equipment- either entirely in-house or as modifications to commercial products - are listed below:

- Baur-Signer rotationally symmetrical ion source for noble gas mass spectrometry. It is employed on two of our single-collector noble gas mass spectrometers, which themselves were built in-house - including ion source emission control, magnet field control and detector electronics.

- High sensitivity compressor ion source for noble gas mass spectrometry (Tom Dooley). The sample gas is compressed into the ion source volume, thus, increasing sensitivity by more than two orders of magnitude. This instrument operates with a miniaturised Baur-Signer ion source on an in-house built mass analyser. Its control and data-reduction software programs (Ionic, Digest, and Final) are all of in-house origin and used on all but one of our noble gas mass spectrometers.

- Gas purification lines for the analysis of noble gases for a variety of types of samples (solids, liquids, and gases). The noble gases are released from the samples either by heating solids in ovens (see below), by heating small grains with infrared lasers, by ablating sample surfaces with an UV-laser, or simply letting liquids degas in vacuum. Gas purification is done with a variety of cold fingers and chemical traps, non-evaporable getter materials, and cryogenic traps.

- A special gas preparation line made entirely from gold for in-vacuo acid etching of samples to release noble gases sequentially by step-wise dissolution of the sample.

- A combined in-vacuum crushing and sieving (CVCS) system for the extraction of noble gases dissolved in fluid inclusions in stalagmites. Contamination of the small noble gas sample amounts with ambient air is minimised in this approach.

- Various high-temperature ovens (~1800°C) based on electron impact heating. They are used for noble gas analysis of extra-terrestrial and terrestrial samples as well as in the preparation procedure of cosmogenic 14C analysis.

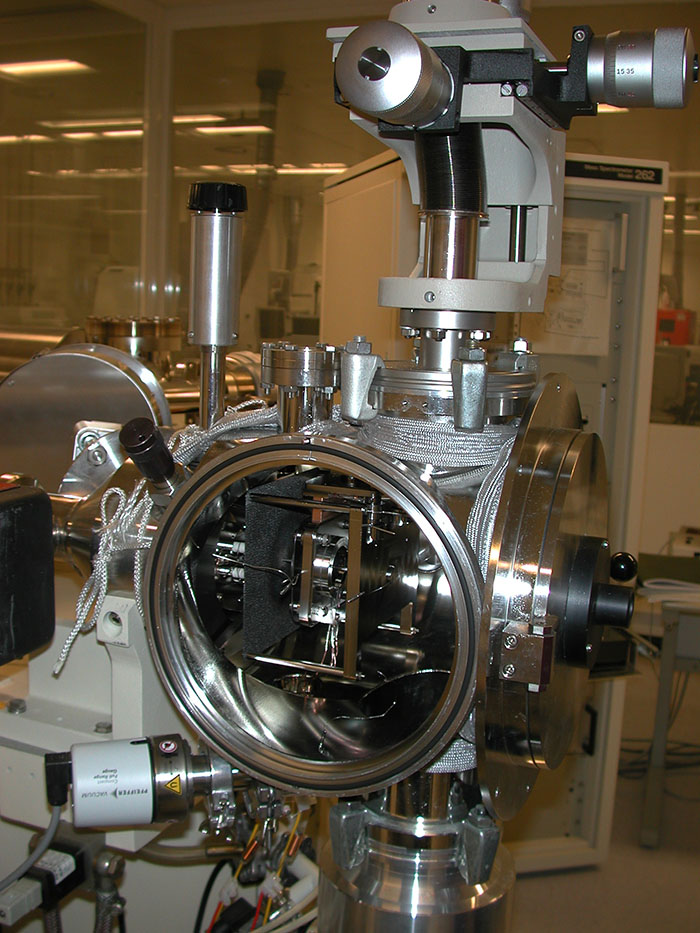

- Development of a thermal ionisation cavity source for enhanced ionisation efficiency in thermal ionisation mass spectrometry (TIMS). This project started with in-house programming of the software code Sofie, with which the physical processes within the cavity can be simulated. Sofie has led to a better understanding of the effects that, e.g., changes in cavity geometry or temperature distribution can have on the performance of the ion source. Based on the results, a proto-type source has been built and is currently being tested as a modification to a MatFinnigan MAT262 instrument. It is providing a more than 10-fold increase in overall efficiency compared to the same uranium samples run on a conventional Triton TIMS instrument.

- Nano-balance for the accurate quantification of small masses and BET measurements. Its operation is based on magnetic levitation.

- Special design and construction of peripheral devices, such as filament baking systems for TIMS, gas calibration apparatuses, high sensitivity vacuum leak testers, etc. - including the related electronical components.

- Various hardware and software improvements to commercially available mass spectrometers.

Contact

Dr. Colin Maden

Inst. für Geochemie und Petrologie

Clausiusstrasse 25

8092

Zürich

Switzerland